Explore Encon's Energy efficient FAN designed for sustainability and growth.

ENCON Energy Efficient EFRP Fan

Encon is the go-to brand when it comes to fixing the problems of operating and managing Axial Flow Fans across clients of all scale & size and across various industries.

We believe that a quality product can only be called so once it has undergone the strictest tests of quality methodologies and standards.

Over time, we developed our own research lab & facilities dedicated to giving you only the very best of all possibilities.

For more details and quote; Please click on enquiry Now!

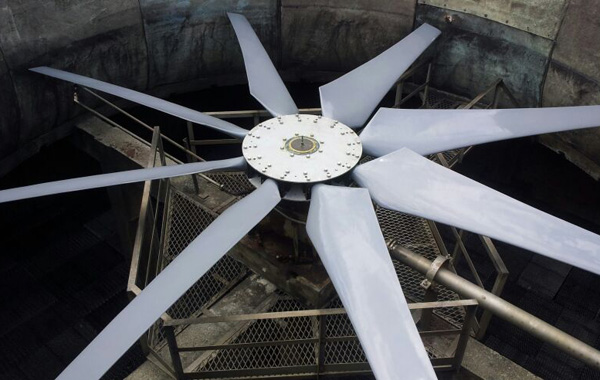

Encon FAN Feature

- Improved Aerodynamic Design

- Energy Efficient

- Negligible Skin Friction

- Higher Lift to Drag Ratio

- Low Noise

- High quality raw material (Fiberglass & Resin)

- Sturdy

- Proven Technology

- Low Maintenance

- High Durability at Less cost

- High Temperature Resistant

Design Criteria for Encon Fan Selection

- Performance

- Optimising fan diameter and no. of blades for given duty conditions.

- Efficiency

- Lowest Power Consumption.

- Erosion & Corrosion Resistance.

- Lowest Maintenance Cost.

- High Temperature Resistance.

- -60°C to 230°C

- Noise

- Lowest Level of Noise without any extra Cost.

- Vibration

- Lowest Down Time of Equipment.

- Design OF Hub

- Minimum Cycling Losses.

- Fan RPM

- Allowable Tip speed for Reducing Noise and Vibration.

- Various System Losses

-

- Entry Losses

- Tip Clearance Losses

- Bearing Losses

- Skin Friction Losses

Difference between Encon Fan & Others

| # | Parameter | ENCON Fans | Others |

|---|---|---|---|

| 1 | Design | Improved Aerodynamic design | Conventional NACA Profiles |

| 2 | Efficiency | 81% - 91.4% | Below 75% |

| 3 | Material | High Grade E Glass Epoxy | Aluminum / Steel / Polyester / Vinyl Ester |

| 4 | Weight | Less Weight | More Weight |

| 5 | Total Axial Thrust Load | Low Axial thrust load on Gear Box | High Axial thrust on Gear Box |

| 6 | Skin Friction | Negligible skin friction due to smooth surface | More Drag losses due to rough surface |

| 7 | Maintenance | Low Maintenance due to high quality raw material and superior manufacturing techniques | Frequent Maintenance required leading to Higher downtime |

| 8 | Product Life | Minimum 10 years* | Aging effect after 2 - 3 years |