Explore Encon's Recovery Fan Stack designed for sustainability and growth

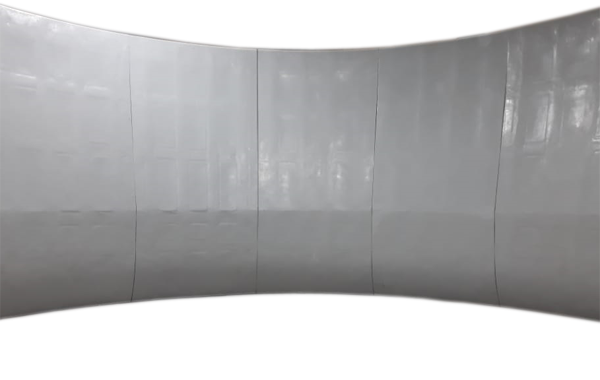

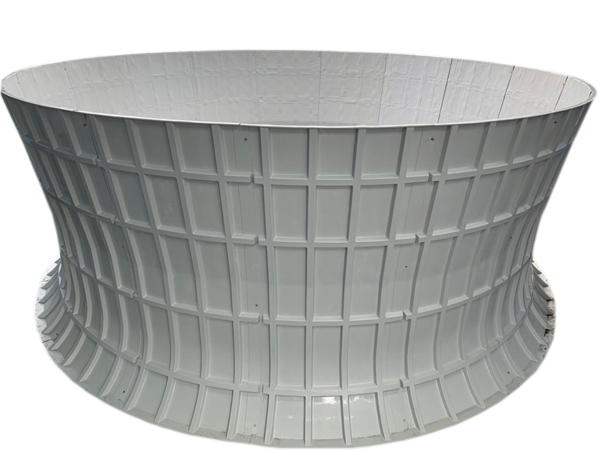

ENCON FRP Fan Stack

The fan stack is an essential part of the cooling tower mitigating pressure loss produced by high input air speed.

The outer surface provides high strength and resistance against climatic conditions and the operation of cooling towers while the internal surface is smooth, so it could improve the air flow parameters for reduced air pressure drop losses and pressure recovery to improve the fan efficiency.

The shape of the classical cylindrical fan stack contributes to lower noise and vibration not only of the fan itself, but the whole cooling tower.

Encon Velocity Recovery Fan Stack (VRFS) is made by RTM manufacturing process, the first in Asia with the output of final finished & ready to use product.

For more details and quote; Please click on enquiry Now!

Fan Stack Features

- Smooth Surface finish on the inside of Recovery Stack helps in reducing Velocity Pressure.

- Tough and sturdy design ensures high durability and long life.

- Improving Fan performance & efficiency.

- Reducing Power consumption.

- Single Panel replacement is possible.

- Low manufacturing time.

- Low Maintenance.

- Manufacturing Range - 4 Feet (1.2 Meters) to 36 Feet (11 Meters).

Fan Stack Comparison between manufacturing process

Fan Stack / Cylinder can be made from a Han lay-up (traditional method) & RTM process (Encon selected method). A small comparison between both the processes highlights the difference between them and their relative advantages and disadvantages.

| # | Parameters | Hand Lay-up (Traditional process). | RTM (Encon selected process). |

|---|---|---|---|

| 1 | Shape Complexity | Shape has to be relatively flat to avoid gaps, overlaps or wrinkles. | Ability to mould large surface areas, complex structural & hollow shapes with smooth finishes. |

| 2 | Strength to Weight Ratio. | Comparatively low. | High strength to weight ratio characteristics. |

| 3 | Glass to Resin Ratio. | Low & inconsistent. | High & consistent. |

| 4 | Uniformity. | Disorientation of fibres & non-uniform thickness due to manual lay-up. | Accurate fibre management & orientation is achievable with uniformity of thickness, fibre loading & uniform shrinkage. |

| 5 | Porosity. | Easy to form air bubbles & voids. | Low resultant voids & air bubbles eliminated. |

| 6 | Lay-up Process | Rollers or brushes are used. | No additional manual tool to be used. |

| 7 | Volatile Emissions | Comparatively high due to open mould process. | Low due to closed mould process. |

| 8 | Post-processing | Involves cutting / finishing of the final product to size & surface quality using a variety of hand & power-operated devices . | Ability to produce near net shape mouldings . |

| 9 | Surface finish | Only one good side to the part. | Components have good surface finish on both sides with less surface & laminate defects. |

| 10 | Cost | Expensive as slow manufacturing process / production rate. | Low due to higher production rates. |

| 11 | Quality & Tolerance | Lack of consistency in dimensional tolerance. Quality is highly dependent on the skill of the laminator. | Quality is maintained due to automated resin infusion. Tighter dimensional tolerances with consistency in product weight. Ability to achieve 0.5 mm to 90 mm laminate thickness. |

| 12 | Physical properties | Compromises the mechanical & thermal properties of the composite. | Higher mechanical & thermal properties. |

| 13 | Tooling. | Cost Low . | Comparatively high . |

| 14 | Health hazards | Creates health risk for the laminator . | Less health risk for the laminator due to no contact with the resin & reduced emissions. |