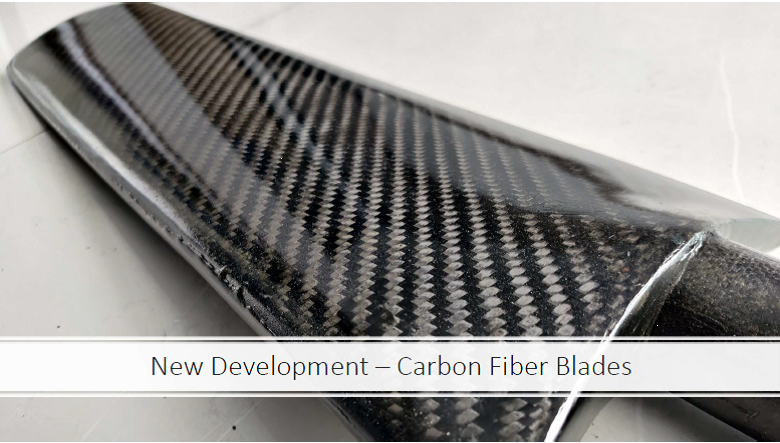

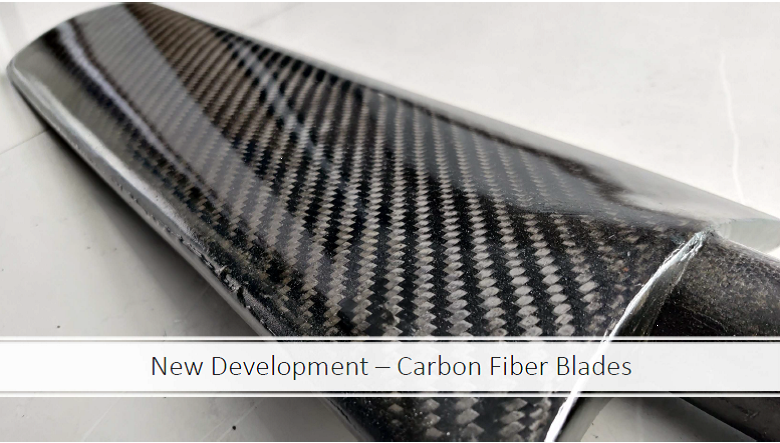

Carbon fibre composites for improved efficiency and extensive lifespan

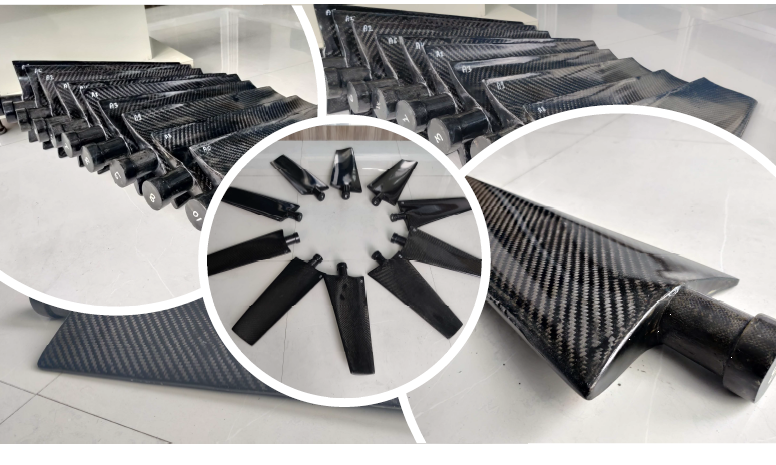

With the advancement in the field of composites, ENCON is using a conscious approach of fan blade design and material selection which takes into account the efficiency as well as the product life. These features will lead to additional energy savings and reduction in maintenance costs. With new development in material science and manufacturing technology, ENCON has already started to develop and export the carbon fibre composites fan blades for cooling industries.

Carbon fibre reinforced polymers (CFRP) is an extremely strong and light composite which weighs about one-fifth as much as steel, but can be better in terms of stiffness and strength, depending on fibre grade and orientation. They do not rust or corrode like metals and offer weight savings by as much as 60%. Hence it has an innovative role in several high performance applications from aircrafts to automobiles and from satellites to sporting equipment.

With Fibre reinforced polymer (FRP) product taking over the cooling industry, due to its many desirable properties, carbon fibre composites is an emerging material which is gradually changing the picture with its additional threshold of resisting erosion, corrosion, high temperature and reduction of skin friction drag. Additionally, the assured life of CFRP fan blades is three times more than that of the FRP material. Unfortunately, the only challenge with the extensive use of carbon fibre is its high production cost. However new development in cost reduction and efficient processing technologies can solve the challenge.

CFRP blades are developed for high efficiency and further improvement in energy savings. So currently we are developing these blades for all applications like Power plants, petrochemicals, chemicals, textiles, mining etc Since economic sustainability is the key factor for all the industries, hence the future of carbon-fibre composites is very positive, with massive potential in many industrial applications.