ENCON’s Multifunctional FRP Clamps

ENCON’s Multifunctional FRP Clamps

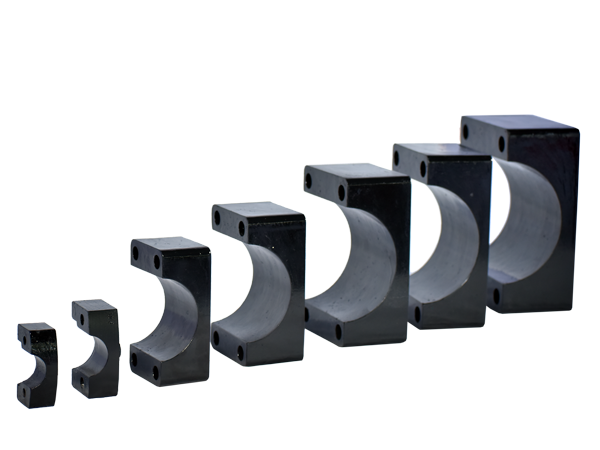

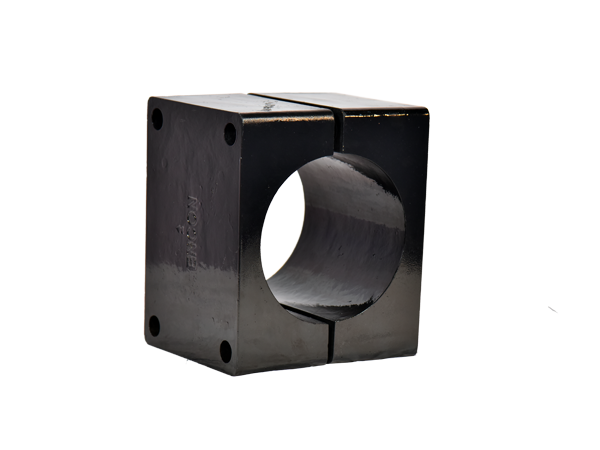

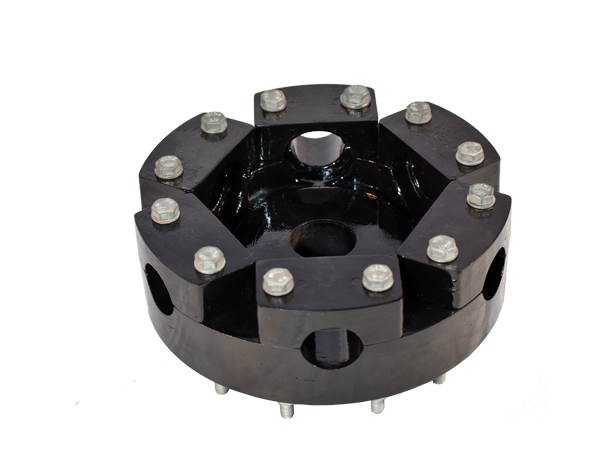

Fiber Reinforced Plastic (FRP) clamps are commonly used to secure FRP blades in cooling towers. FRP clamps are corrosion-resistant and lightweight, making them an ideal choice for use in cooling towers where exposure to water and harsh environmental conditions is common.

These clamps are designed to grip the blade securely and prevent movement, while also allowing for easy installation and removal. The use of FRP clamps also helps to minimize damage to the blade, as they distribute the load evenly across the blade surface.

When selecting FRP clamps for FRP blades used in cooling towers, it is important to consider factors such as the size and shape of the blade, the type of cooling tower, and the environmental conditions in which the tower will operate. It is also important to follow the manufacturer's guidelines for installation and maintenance to ensure the longevity and reliability of the clamps and blades.

For more details and quote; Please click on enquiry Now!

Salient Points of ENCON’s FRP Clamp

- Strength to weight ratio is three times more of the stainless steel or Metallic one..

- Very lightweight compared to metal. (Due to considerable reduction in self-weight, the axial load imposed on the other components will be reduced, hence reduction in overall vibration and related stresses)..

- Achieves homogeneity of material between blade neck and holding block which result in enhanced damping effect (reduction of vibration amplitude)..

- Durability: Due to the uniform distribution of vibratory loads over the fan blade and clamp, the maximum amplitude is absorbed by the clamps and hence operational life of the fan blade will be improved significantly..

- Vibration damping and reduction in the development of micro-cracks under high vibration loads..

- High corrosion resistance properties make it the best choice for seawater cooling tower operation too..

- Non-conductive: FRP clamps are non-conductive, which makes them ideal for use in electrical applications. They can also help to prevent electrical arcing and reduce the risk of electrical shock. .

- Customizable: FRP clamps can be custom-designed and manufactured to meet specific application requirements, including size, shape, and material composition.

Overall, ENCON’s FRP clamps offer several advantages over metallic clamps in terms of corrosion resistance, weight, strength-to-weight ratio, non-conductivity, reliability and durability.

Comparison between FRP and Metallic Clamps

| # | Characteristic | FRP Clamps | Metallic Clamps |

|---|---|---|---|

| 1 | Corrosion resistance | Highly resistant to corrosion from water, chemicals, and other environmental factors | Susceptible to corrosion, especially when exposed to water and chemicals |

| 2 | Corrosion resistance | Lightweight and easy to install | Heavy and can be difficult to install |

| 3 | Strength-to-weight ratio | High strength-to-weight ratio, meaning they can support heavy loads while remaining lightweight | Lower strength-to-weight ratio, which may limit the loads they can support |

| 4 | Homogeneity | Homogeneity with neck and clamp materials | No Homogeneity |

| 5 | Vibration absorption/ Vibration | Damping Enhanced damping effect | Less damping effect |

| 6 | Customization | Can be custom-designed and manufactured to meet specific application requirements | Limited customization options |

| 7 | Durability | Durable and long-lasting, even in harsh environments | Susceptible to degradation from exposure to environmental factors |

| 8 | Conductivity | Non-conductive, making them ideal for use in electrical applications | Conductive, which can create electrical hazards in certain applications |

| 9 | Cost | Generally more expensive than metallic clamps | Generally less expensive than FRP clamps |

| 10 | Life | More as compared to metallic | Less due to corrosion, erosion. |