ENCON’s Multifunctional CFRP Fan

Encon's Carbon Fiber Reinforced Polymer (CFRP)

What are CFRP Fan?

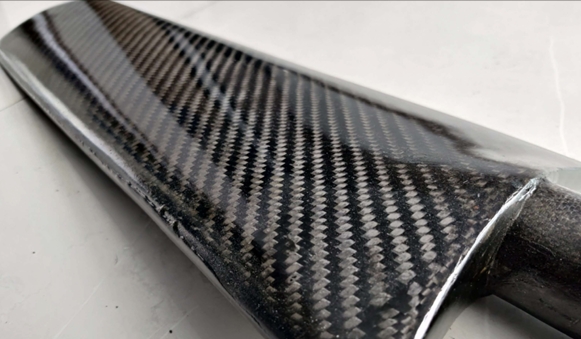

CFRP, a composite of carbon fibers and a polymer matrix, achieves a remarkable balance of strength, lightness, and durability. This makes it a superior material for numerous demanding uses.

The innovative aerodynamic design, combined with aerospace-grade carbon fibre materials and advanced resin systems, delivers a return on investment (ROI) within one year or less. This performance spans across electrical, thermal, and mechanical energy savings. Additionally, it ensures extended operational life and exceptional efficiency of axial flow fans, while minimizing maintenance costs. The enhanced durability of rotary components—such as gearboxes, shaft assemblies, motors, and pulley drives—further adds value, offering significant long-term benefits to customers.

For more details and quote; Please click on enquiry Now!

INTRODUCTION TO CFRP FAN

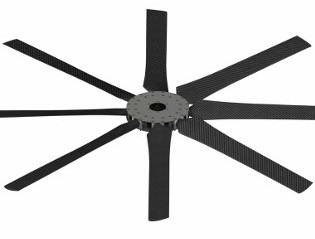

ENCON's Reliablades are specifically crafted for heavy-duty industrial use.

- Superior Performance & Efficiency:

- High strength-to-weight ratio enables higher RPM and air delivery

- Aerodynamic design ensures maximum airflow with low energy use

- Low friction and reduced drag boost overall system efficiency

- Designed to work with existing motors and gearboxes, no upgrades needed

- Reliability in Harsh Environments:

- Corrosion & erosion-resistant against chemicals, moisture, saline air and UV rays.

- Withstands mechanical fatigue from continuous or cyclic use

- Thermal stability maintains blade shape at high operating temperatures

- Ideal for power plants, refineries, cement, and coastal installations

- Low Maintenance, Long Life:

- Highly durable material - minimal wear and tear

- Reduced chances of cracks, deformation, or corrosion

- Less frequent servicing leads to lower downtime and OPEX

- Consistent performance over years of operation

- Easy Installation & Design Flexibility:

- Lightweight for quick handling and retrofitting into current systems

- No structural changes required–fits into existing infrastructure

- Custom blade profiles available for specific airflow or noise goals

- Efficient installation = savings in time and labor

NEXT-GENERATION BLADES FOR NEXT-LEVEL INDUSTRY

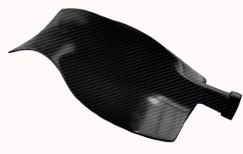

At ENCON, we don’t believe in a one-size-fits-all approach. Each blade profile you see here is designed to meet specific performance and environmental requirements.

The improved aerofoil shape enhances efficiency, leading to greater energy savings that clients can utilize to achieve better cooling performance, if desired.

- Blade geometry is customized depending on airflow needs —whether it’s for high static pressure, low noise, or energy optimization.

- Industrial setups like power plants, refineries, and various systems each require different profiles for maximum efficiency.

- Each profile is aerodynamically engineered for maximum air delivery with minimum resistance, ensuring better performance at lower energy input

WHY ENCON FAN ARE THE MOST RELIABLE?

Our Failure rate is 0.0025 % across our 5,58,000 + Installations across 45 countries!

Using Formosa (Germany & Taiwan) C-Glass Multiaxial Fiber Glass Systems, the end product experiences

- Superior Structural Strength & Fatigue Resistance: Enhances durability and mechanical load-bearing capacity.

- Dimensional Stability: performance across Reliable a wide temperature and humidity range

- Optimized Resin Compatibility: Excellent bonding with epoxy resins ensures long-lasting composites.

Using Huntsman Advanced (Europe) & Aditya Birla Chemicals (India) Epoxy Resin Systems, the end product experiences:

- Stronger interlaminar bonding, smooth surface finish, and uniform resin distribution ensure robust CFRP integrity

- Exceptional thermal, chemical, and water resistance enables reliable performance in harsh environments

- Advanced resin systems minimize degradation from acidic/alkaline exposure while enhancing durability.

- Sustainable Recyclamine® technology allows recovery and reuse of carbon fibers from end-of-life components

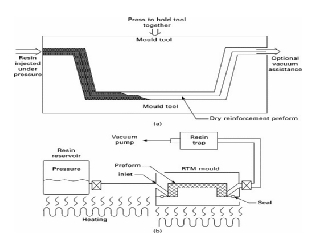

Resin Transfer Molding: The Foundation of Strength, Efficiency & Quality

- Uniformity of Construction

- Homogeneity in Mixing

- Skillful Execution of Process

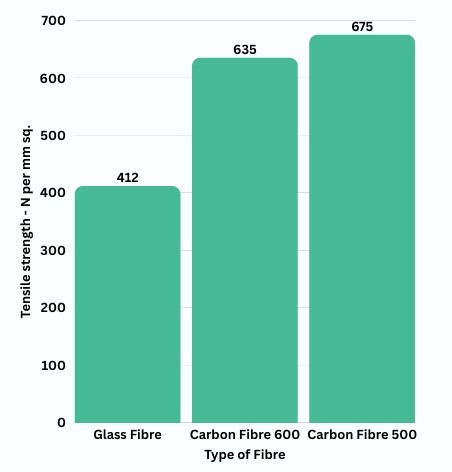

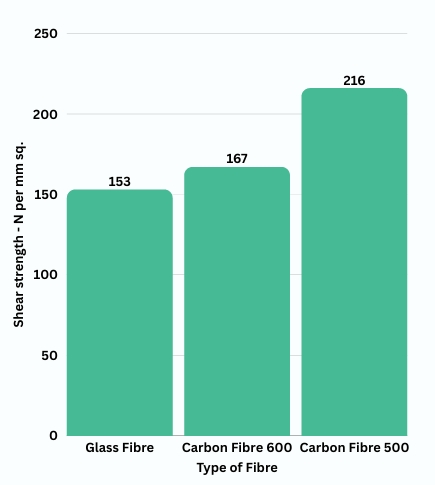

As the data reveals, Carbon Fiber possesses a considerably superior ability to withstand pulling forces. In fact, our analysis shows that carbon fiber is over 60% stronger than Glass Fiber in this critical performance metric

Encon’s latest innovation in fan blade technology— Carbon Fibre Blades—offers cutting-edge advantages that deliver efficiency, durability, and performance like never before

Tensile Strength: Up to 1100 MPa – higher than steel

Density: Only ~1.6 g/cm³ – nearly 5x lighter than steel

Thermal Stability: Low thermal expansion ensures dimensional stability in varying temperatures

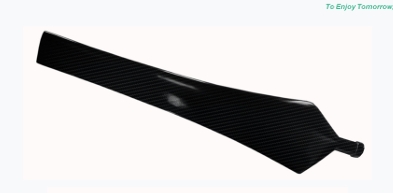

Aerodynamic Blade Design:

- Minimizes air drag

- Enhances airflow

- Reduces turbulence and power consumption

Analysis reveals that Carbon Fiber (up to 216.29 N/mm²) offers substantially greater resistance to shear stress than Glass Fiber (152.39 N/mm²). This makes Carbon Fiber the preferred material for components subjected to high-speed rotation

These blades are engineered for performance, longevity, and efficiency—setting a new industry standard.

High-Speed Rotation: CFRP fan operate at high speeds, subjecting their blades to significant twisting and shearing forces

Shear Strength Importance: Higher shear strength means the fan blades can better withstand these forces without deforming or failing.

Durability and Reliability: This is crucial for maintaining the fan's performance, efficiency, and longevity, especially in demanding industrial applications

COMPLIANCE & ENGINEERING EXCELLENCE

Certified Standards Adherence

- Manufacturing Standards: ASTM, BS

- Fan Installation Standards: CTI, API

- Facility Certifications: ISO 9001, ISO 45001, ISO 14001

Engineering & Validation Infrastructure

- Equipped with India and Asia’s only AMCA Tunnel Bench for performance testing

- Use of CATIA, SolidWorks & Ansys for advanced simulation and structural analysis

- Custom-developed fan selection software enables optimal fan design for complex retrofits

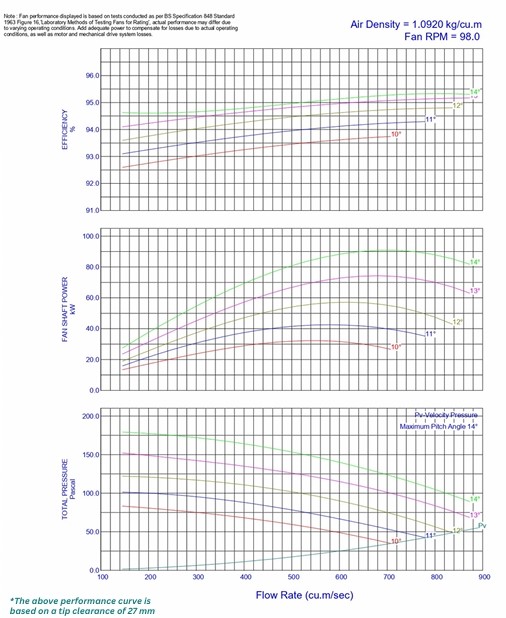

Performance Curves and Efficiency Overview

- Minimum Efficiency: The lowest efficiency visible on the graph is around 93% at the lower flow rates for the 10-degree pitch angle.

- Fan Installation Standards: CTI, API

- Maximum Efficiency: The highest efficiency reaches approximately 95% at higher flow rates for several pitch angles (mainly 12, 13, and 14 degrees).

WHY CFRP FAN IS A SMART INVESTMENT

- Lightweight & High Strength:

- Reduces motor stress

- Easier to install and maintain

- Corrosion Resistance:

- Performs better than FRP fan in moist, chemical, or salty air

- Longer life span, even in harsh industrial zones

- Energy Efficiency:

- Lower rotational inertia = reduced power use

- Fan Installation Standards: CTI, API

- Saves up to 30-35% energy in various applications

- Noise Reduction:

- Carbon fiber dampens vibrations

- Ideal for environments needing quiet operation

Industrial Applications

CFRP fan are engineered for reliability in harsh industries:

Power Plants: CFRP fan enhance cooling tower efficiency with lightweight blades and withstand corrosive gases in boiler systems.

Refineries: These fans improve heat exchange processes and operate effectively in environments with high-temperature vapors.

Cement Industry: CFRP fan manage extreme heat in kiln exhaust systems and support crucial processes like clinker cooling and dust collection.

Mining: CFRP fan ensure effective ventilation for underground air quality and are built to endure abrasive particles.

CFRP FAN TECHNOLOGY: A CASE STUDY IN GLOBAL REFINERY EFFICIENCY

Challenge: Turkish Refinery's existing CT fan (Fan No.560K001B) was underperforming, requiring significant energy consumption (253.44 kW)

Solution: Installation of a new ENCON CFRP fan (Model No. ENC-00401-80, Diameter 10363mm, 8 Blades) with optimized blade angle

Result –

Increased Airflow: New fan achieved 770.73 CMS, a 2.47% increase from the old fan's 752.19 CMS.

Significant Power Reduction: New fan consumed only 159.95 kW, resulting in a 36.89% reduction in power consumption

Even Greater Potential Savings (Maintaining Old Airflow): Analysis showed that maintaining the old airflow with the new fan would only require 146.71 kW, leading to a potential 42.11% power reduction

THE COMPLETE ENCON VALUE PROPOSITION

Empowering a Greener, More Efficient Tomorrow.

- We envision a future where our innovative products are integral to our customers' success, driving tangible improvements in their daily operations and contributing to a healthier planet.

- By focusing on airflow optimization, durability, energy conservation, and proven reliability, we empower organizations to achieve operational excellence while minimizing their carbon footprint and maximizing long-term savings.

- We are committed to providing solutions that not only meet today's needs but also anticipate the challenges of tomorrow, ensuring our customers remain ahead of the curve.