Carbon Fiber Drive Shaft, A Superior Alternative to Traditional Steel

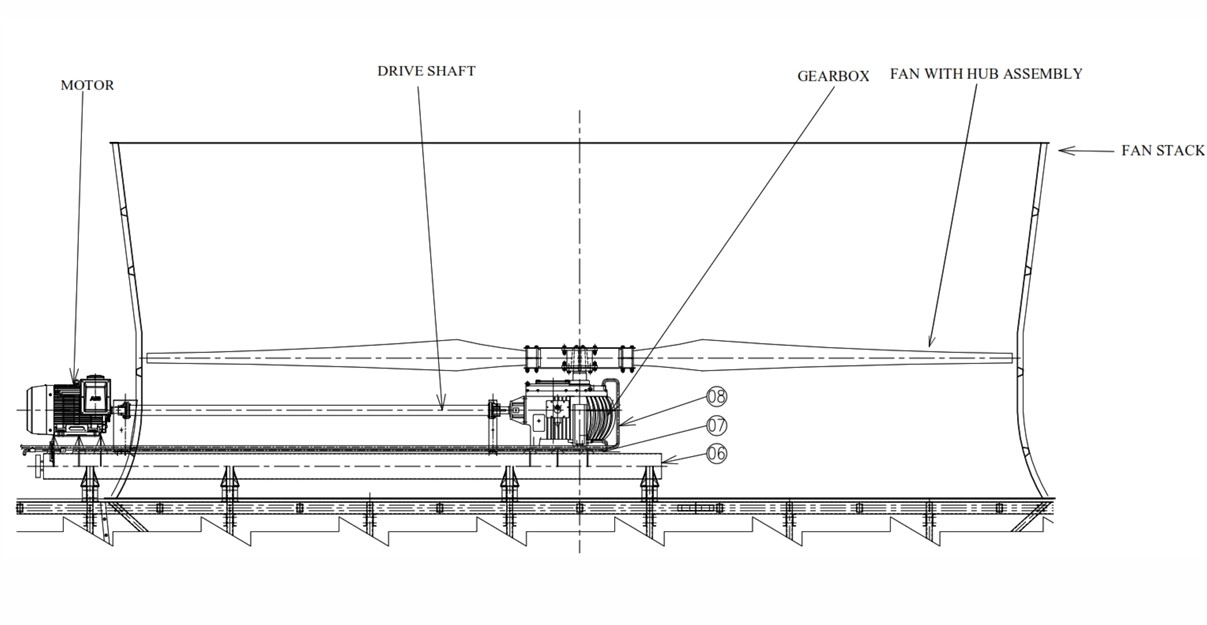

Cross Sectional Of Cooling Tower

For more details and quote; Please click on enquiry Now!

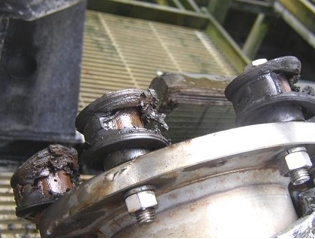

Problem with traditional Steel Shaft

- Extremely heavy (100–200kg)

- Corrosion prone (chlorine exposure)

- Rubber bushings degrade quickly

- High vibration and frequent misalignment

- Complex installation/removal process

- Short lifespan: 5–7 years

- Higher cost due to frequent maintenance

Corrosion Prone:

| Effects of Corrosion |

|---|

| 1) Loss of Material cause Imbalance - Vibration |

| 2) Entire assembly has to be replaced. Assembly Balance is done - Part (hub) replacement not possible. |

| 3) Service Life is 5-7 years. Results in RECURRING CAPITAL COSTS |

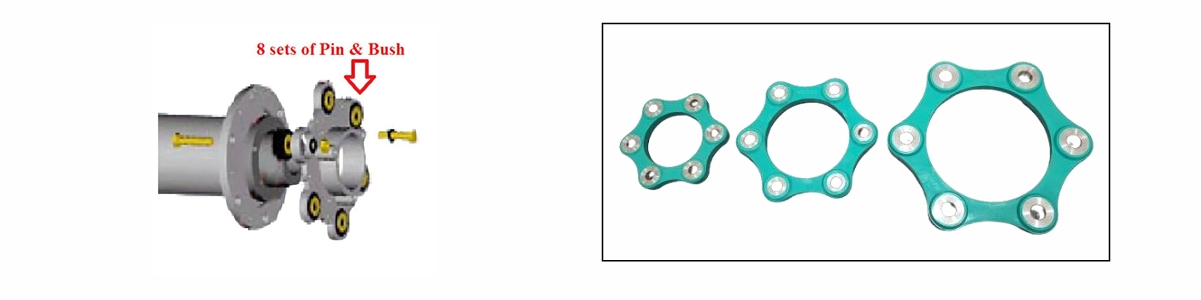

Degraded Rubber Bush:

| Multiple Parts | 16 sets of Pin & Bush |

|---|---|

| Rubber bush degraded by Chlorine | Misalignment capacity gone - Vibration Frequent Replacement |

Flexible Joint Difference –

| 8 sets of Pin & Bush per End | Unitized (1 piece) Flexible Disc per End |

| Low service life rubber | Min 5 years - Composite |

| Minimized misalignment tolerance has led to performance loss due to material hardening. |

The misalignment capacity is three times the standard threshold. |

Why ENCON CARBON Composite Shafts?

Weight:

Experience unparalleled ease of handling with an ultra-lightweight design, ranging from just 09 to 70 kilograms. This significantly reduces strain during installation and maintenance.

Material Properties:

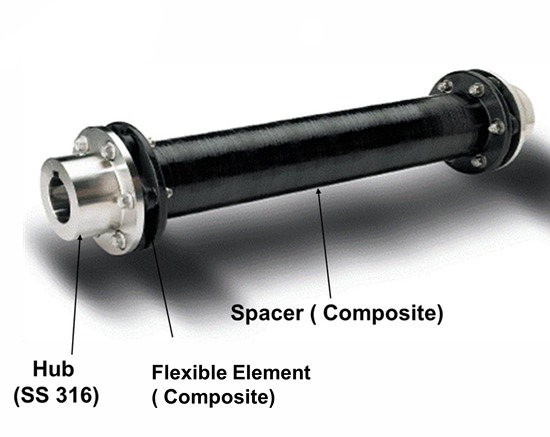

Built with SS316 stainless steel and advanced CARBON composite, this system delivers exceptional corrosion resistance for reliable performance in any environment. Hub (SS 316) Flexible Element (Composite) Spacer (Composite)

Operational Benefit:

Minimize wear and tear on your valuable equipment. The design inherently produces minimal vibration, contributing to a significantly longer lifespan for Gearbox and connected rotary machinery.

Usability:

Installation and removal are designed to be swift and secure. This efficiency saves valuable time and resources during setup and any necessary maintenance.

Carbon Composite Materials: A Comprehensive Overview

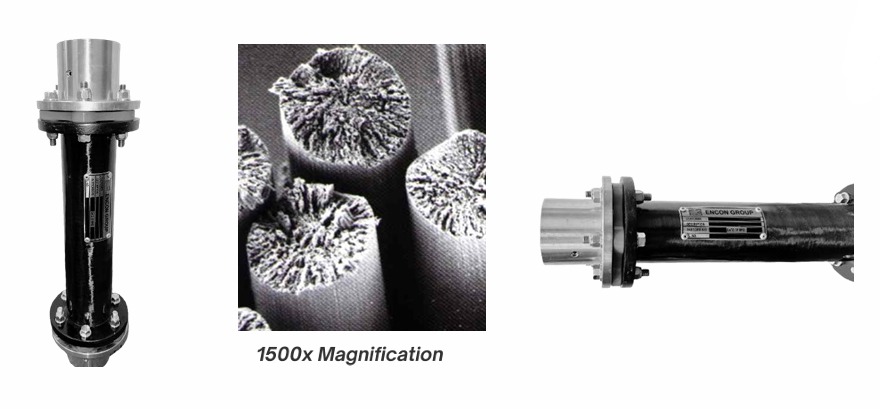

These high-performance materials, known as advanced carbon composites, usually comprise a polymer base strengthened by continuous fibers aligned in a predetermined way.

Types of Fiber Used:

• Fiberglass

• Carbon/Graphite*

Technical Advantages

Key Benefits:

• Flexible Joints

• Misalignment Tolerance

• Thermal Expansion

• High Strength-to-Weight Ratio

The composite disc joint boasts a longer minimum service life (5 years), three times the standard misalignment capacity, and avoids hardening issues associated with the low service life rubber used in the pin and bush design.

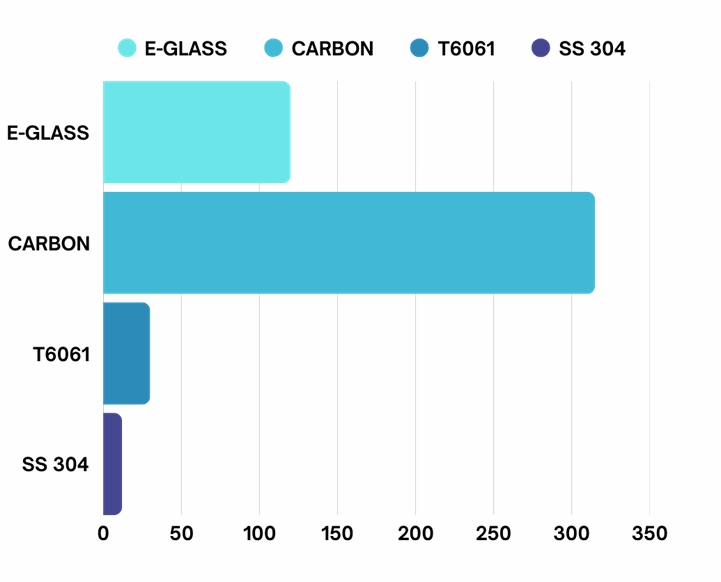

Carbon composite materials: A graphical perspective

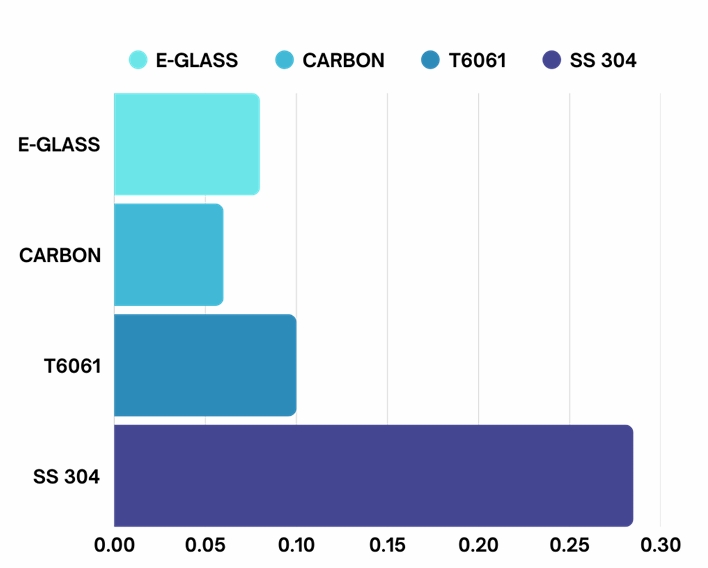

Density Comparision:

Lightweight design facilitates easier handling, minimizes stress on bearings, and reduces vibration.

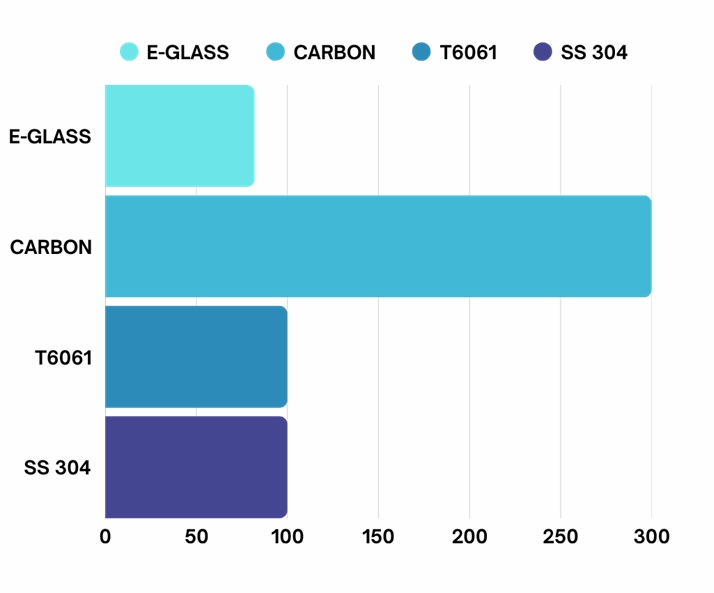

SPECIFIC STIFFNESS x 1000000 INCHES (MODULUS / DENSITY)

Specific stiffness, calculated as modulus divided by density, highlights material stiffness relative to its weight. Carbon composite's superior specific stiffness (demonstrated by less sag in a rod comparison) allows Encon couplings to achieve longer spans compared to steel and aluminium.

SPECIFIC STIFFNESS x 1000000 INCHES (Tensile Strength / DENSITY)

Carbon fiber boasts a specific strength six times greater than comparable industry materials when considering tensile strength relative to density. Ultimately, carbon composites offer a superior combination of being lighter, stiffer, and stronger than both aluminium and stainless steel.

Steel vs. Carbon Fiber Driveshafts: A Comparison

| # | STEEL | ENCON CARBON FIBRE COMPOSITE | BENEFITS |

|---|---|---|---|

| WEIGHT | HEAVY (100-200 KG) | ULTRA LIGHT (09-70 KG) | • Faster Installation & Alignment • Easy Maintenance |

| VIBRATION | HIGHER (> 10 MM/SEC) | MINIMAL (< 2 MM/SEC) | • Longer Bearing and End Equip life. • Lesser Down Time |

| CORROSION | HIGH | NO CORROSION | • Min Ownership cost during for life of Cooling Tower |

| FLEXIBLE JOINT | PIN & BUSH (8 SETS) | UNITIZED (1 PIECE) | • Simple Replacement • Reduced Maintenance cost & time |

| SERVICE LIFE | 5-7 YEARS | CT LIFE TIME | • No Recurring Capital Cost |

| DOWNTIME TIME & COST | HIGHER | MINIMUM | • Trouble free operation |

Performance & Testing

Torque Performance:

Proven to withstand peak loads without failure, ensuring reliable performance under demanding conditions.

Fatigue Resistance:

Exceeded 43,000 motor start cycles, demonstrating exceptional resistance to repetitive stress and a long service life.

Spacer Longevity:

Engineered for a 20+ year lifespan, minimizing replacements and reducing long-term operational costs.

UV Exposure Resilience (India Testing):

Showed no property loss under intense Indian UV radiation, ensuring long-term material integrity in such environments