Cooling Tower Thermal capability improvement

Problem Statement & Implementation Strategy

PROBLEM

STATEMENT

Improve the thermal efficiency improvement of an induced draft cooling tower to reduce cold water temperature for an increase in overall plant production efficiency.

Thermal Understanding of Fills

The

heat transfer rate in a wet cooling tower system is directly dependent on the

factor of total water surface that the system is able to contact with the mass

airflow. The longer the greater area of water stays in contact with the air the

higher the rate of heat transfer from the water to the air through specific

heat required for evaporation.

This thermal relation between water surface exposure and heat transfer is fundamental to all types of cooling towers. The aim of all cooling medium is to thus physically maximize these factors to achieve maximum temperature drop across the system.

SOLUTION

The most significant factor in a cooling tower that directly determines the water surface exposure is the fills used. Upgrading the fills, keeping the water chemistry and other factors in consideration is the most reliable and effective method of improving the rate of heat transfer in the system.

Existing fills - Splash fills (V- bar)

Splash fills are the least thermally effective fills in the current market but are best suitable for applications with the worst water quality conditions.

The fills had to be replaced with a higher thermal efficient option keeping in mind the water chemistry and quality conditions to prevent an unnecessary increase in maintenance cost.

The Cooling Tower is designed for 4 (Four) Cells in series construction of RCC structure with a total water flow rate of 6612 M3/Hr

Existing condition – Splash fills (V-Bar)

TOTAL WATER FLOW NO. OF CELL OPERATING HOT (INLET) WATER TEMP. COLD (OUTLET) WATER TEMP. WET BULB TEMP. RANGE APPROACH | 4000 M3/Hr 4 39°C 29°C 25.5°C 10°C |

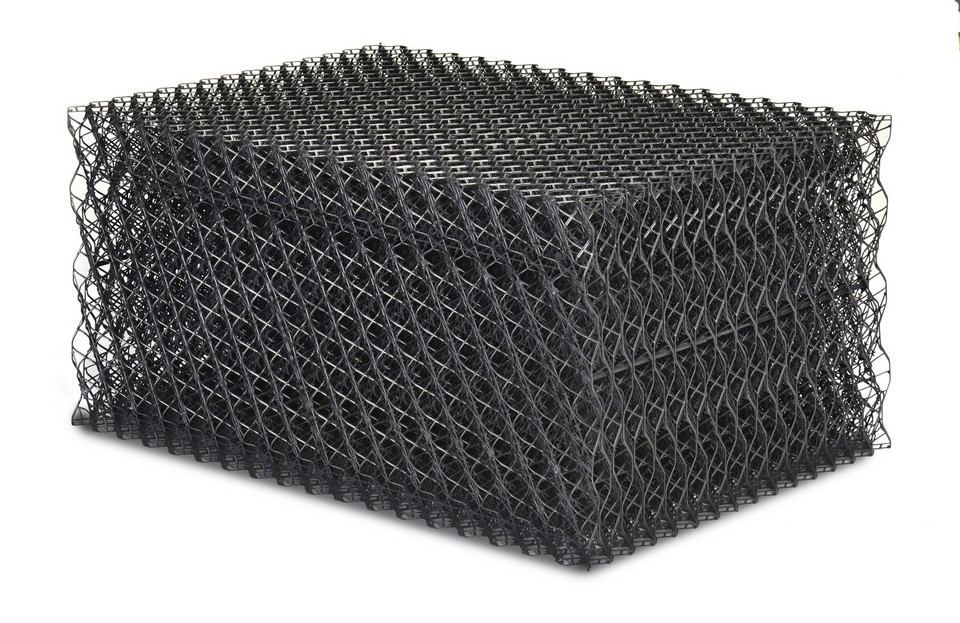

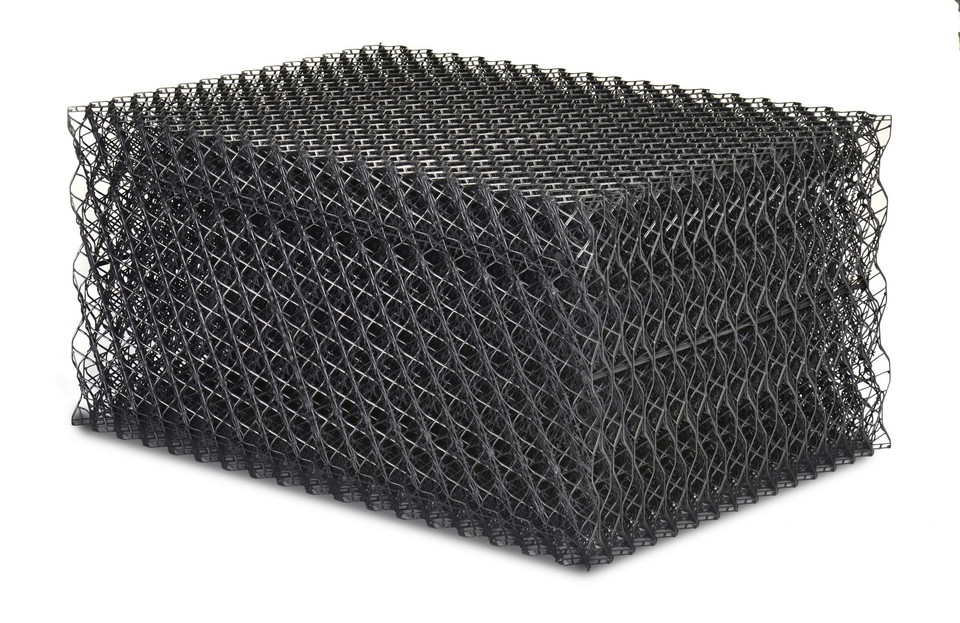

TRICKLE GRID FILLS MATERIAL - Poly Propylene SPECIFIC SURFACE AREA - 125 M2/M3

FLUTE SIZE - 20 MM

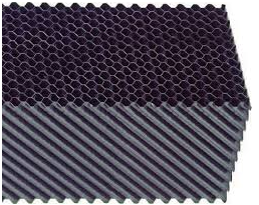

| PVC FILM FILLS MATERIAL - Poly Vinyl Chloride SPECIFIC SURFACE AREA - 157 M2/M3

FLUTE SIZE - 19 MM

|

Proposed solution - Hybrid Fills (TG + PVC Films Fills)

TOTAL WATER FLOW NO. OF CELL OPERATING HOT (INLET) WATER TEMP. COLD (OUTLET) WATER TEMP. WET BULB TEMP. RANGE APPROACH | 6612 M3/Hr 4 39.5°C 29.5°C 25.5°C 10°C |

IMPLEMENTATION

Hybrid combination (Trickle Grid + Film fills) were selected to replace the V-bar splash fills.

RESULTS

The Cold water temperature was reduced by 3°C (Range was increased by 3°C) and the Approach was reduced by 2°C, a feat of colossal improvement in an increase in overall plant output and productivity. This proves the significance and importance of proper component selection and thermal data experience in cooling towers.

Before Modification HOT (INLET) WATER TEMP COLD (OUTLET) WATER TEMP 31°C WET BULB TEMP 26°C RANGE 7°C APPROACH 5°C | After Modification (Encon) HOT (INLET) WATER TEMP COLD (OUTLET) WATER TEMP 28°C WET BULB TEMP 25°C RANGE 10°C APPROACH 3°C |